Collaboration: Teakia x Raga Svara

Raga Svara, featured in the Conde Nast Traveller Magazine, located in Kasturbadham, India, is a learning and healing institution. It is difficult to place it neatly in any category. To put it in familiar categories. Raga sits between a wellness retreat, an ashram, an ayurveda centre, a learning institution and a cultural centre.

We here at Teakia had the wonderful opportunity to collaborate with the folks at Raga Svara and help them to pick the right piece of teak furniture for their specific needs. Being described to us as being built within a wooded site with large trees and fruit orchards, it was important to stick to a natural theme.

Chapter 1: Drawing Board

Like the beginning of any script, we start from the drawing board. Every single piece of furniture goes through certain steps of vigor.

Step 1: Sketches.

Before and proper sketches can take place, photographs of sample designs are looked at and used as a base.

Here at Teakia, sketch comes in 2 forms.

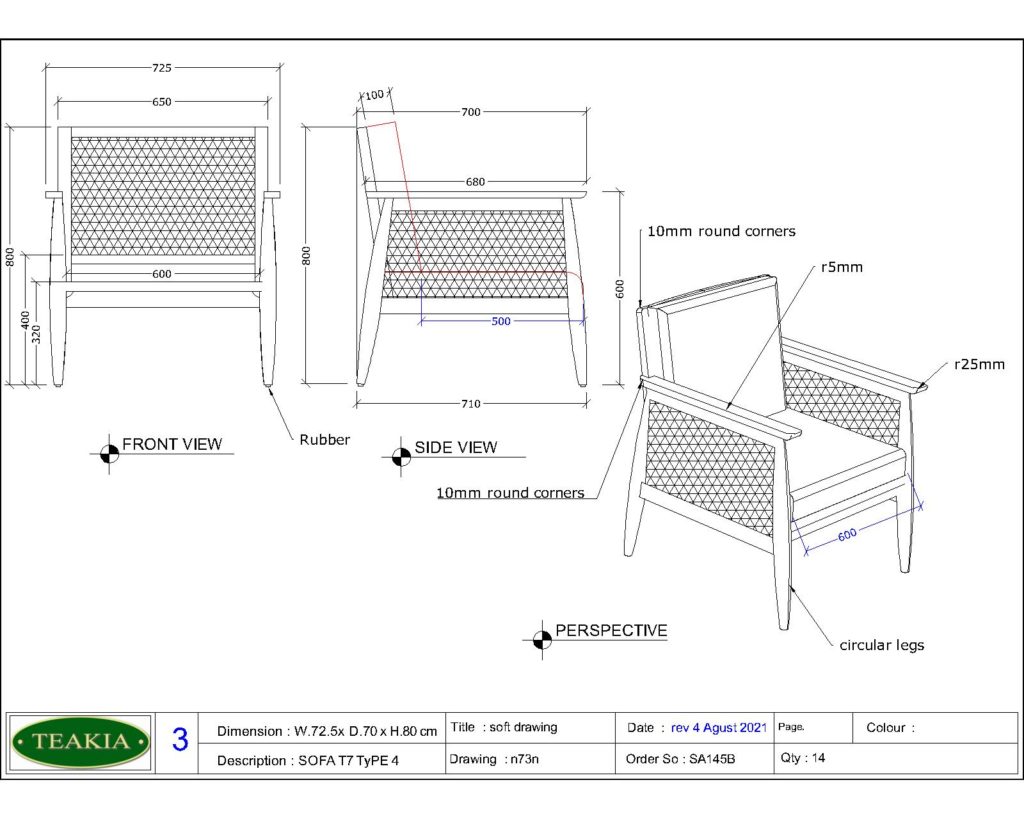

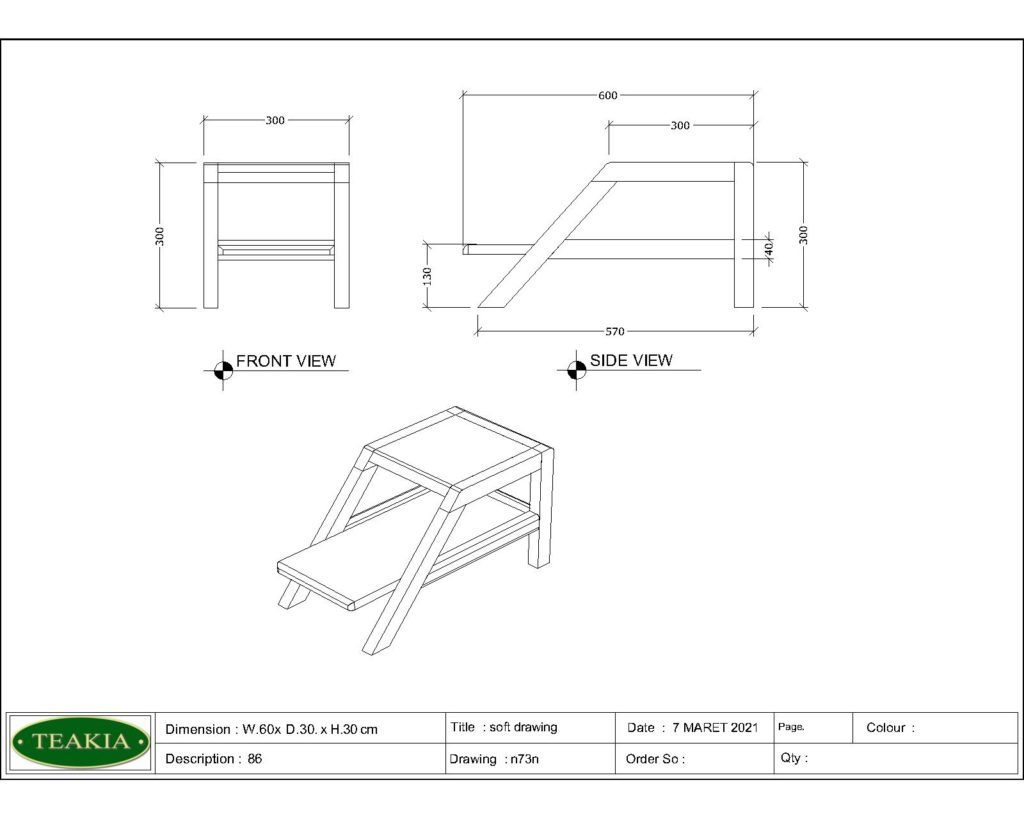

2D Sketch – This is a done to make sure that the dimensions are correct and this sketch is later referred to by our skilled craftsmen to create the perfect piece.

3D Sketch – This is a visual representation of what the finished product can look like, this is mainly for the client to visually look at the image before giving the go for production.

Chapter 2: Pre - Production

After the sketches have been completed and the 3D drawings have been completed and been looked at by the client, the project then moves on to the pre-production phase, samples of each different pieces of furniture are created before they can go into mass production. This enables 2 things. Firstly, the sample makes it easier for our production team in Indonesia to have a base reference for what the product should look and feel like, this includes the surface of the product, whether it is smooth or rough as well as the different coating that might be used for the desired look. Secondly, having a working sample also enables the QC (quality control) to be maintained, and any products falling below that range are either sent back for re-production, or are discarded and later repurposed for a different cause. Being able to deliver high quality teak furniture to our client is what we aim to do.

Chapter 3: Production

Once the samples have been completed and the quality of the samples are up to the standard, the next phase of the project moves onto the mass production of all of the individual products. This collaboration with Raga Svara included products such as and not limited to, Teak Wardrobe, Teak Bedframes, Teak Rattan Bedframes, Teak Writing Table, Teak Massage Table, Teak Buffet Table, Teak Swing as well as Teak Sofas, Teak TV Consoles, and Teak Outdoor Sets. Production takes on different stages, it all starts with kiln drying the wood for a specific amount of time before any construction can take place, this makes sure that in the future there are no issues of warping or cracking of the furniture and allows for sturdy construction. Depending on the item, the raw materials are then moved to different sections of the factory where construction can begin.

Chapter 4: Quality Control & Packaging

Making sure that each individual product is up to our standard is very important to us here at Teakia. Each product individually is checked at various stages before it is packaged for shipping. Firstly, each joint is throughly inspected for defects, secondly the finish of the product is checked to make sure there are no sharp ends or any scuff marks that may have happened during production. Lastly, the colour of the product is checked to ensure that it matches the specifics. For products that have drawers and doors, each of them are checked to see if they move smoothly across and that there are no issues with the the rails or the drawers/doors itself.

After an item has passed QC it moves on to packaging where each product is packed tightly with reclycled cardboard and other layers, this is done to prevent any damage to the products during transport. Smaller products such as side tables are packaged in a box rather than individually.

Chapter 5: Delivery

We have done deliveries thoughout the world, some of which include Malaysia,Maldives, India, Europe, as well as Australia and USA. We pride in ourselves in being able to deliver products throughtout the entire globe.

After the products have been packaged they are then loaded onto a container, 40ft high cubic in this case and send to the destination. Sometimes our help maybe required for the assembly of the products and therfore trained staff are also sent to the destination, once the products have reached. In this project, the delivery address was in INDIA.

DESTINATION

Here is a look at the furniture once it was delivered to Raga Svara, compared to when it was in production at our factory.

YOGA PLATFORM

CHAIRS AND BUFFET TABLE

MASSAGE TABLE AND STOOL

TEAKIA x RAGA SVARA